Maintaining stable pressure in industrial systems has always been essential for ensuring equipment safety, product consistency and process efficiency. Across oil refineries, pharmaceutical units, chemical plants, food processing lines and water treatment facilities, the pressure reducing valve (PRV) plays a critical role in controlling downstream pressure. This article provides a fully engineered, SEO-optimized explanation of Direct-acting, Pilot-operated and Dome-loaded PRVs, along with their working principles and major industrial applications.

What Is a Pressure Reducing Valve? (PRV Definition for Featured Snippets)

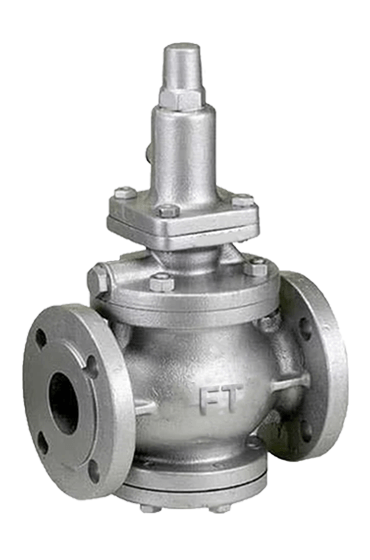

A pressure reducing valve is a mechanical device designed to automatically reduce high inlet pressure to a controlled, lower downstream pressure. It operates without external power by balancing spring force, diaphragm movement or dome pressure against the downstream pressure.

This definition reinforces search intent and improves ranking potential for “pressure reducing valve meaning” and “what is a PRV”.

How a Pressure Reducing Valve Works

A PRV regulates pressure using a force-balancing mechanism. Downstream pressure acts on a diaphragm or piston. When downstream pressure increases above the setpoint, the valve moves toward a closed position. When downstream pressure drops, the valve opens to restore the required level. This self-adjusting action ensures stable pressure in fluctuating conditions, making PRVs indispensable for industrial utilities.

Types of Pressure Reducing Valves

Below is a structured overview of the three major PRV types, optimized for long-tail keywords.

1. Direct-acting Pressure Reducing Valve

A direct-acting pressure reducing valve uses a spring and diaphragm directly connected to the main valve. The spring force determines the pressure setpoint.

Key Engineering Characteristics

-

Compact and simple construction

-

Immediate mechanical response

-

Best for low to medium flow rates

-

Minimal maintenance required

-

Cost-effective for general pressure regulation

Typical Industry Use

Direct-acting PRVs are widely used in:

-

Compressed air lines

-

Instrumentation gases

-

Small process water lines

-

Utility points in pharmaceutical and food plants

-

Packaging utilities and support systems

Their simplicity and reliability make them suitable for non-critical applications where moderate accuracy is acceptable.

2. Pilot-operated Pressure Reducing Valve

A pilot-operated PRV uses a smaller pilot valve to control the main valve. The pilot senses downstream pressure and adjusts the main valve with superior accuracy.

Key Engineering Characteristics

-

High pressure accuracy

-

Excellent stability under varying demand

-

Higher flow capacity

-

Lower pressure droop

-

Ideal for large pipelines and steam systems

Typical Industry Use

Pilot-operated PRVs are preferred in:

-

Oil and gas refineries

-

Steam distribution networks

-

Chemical reactors

-

Power generation units

-

District heating systems

Their ability to maintain tight pressure control under dynamic conditions makes them critical for high-risk processes.

3. Dome-loaded Pressure Reducing Valve

A dome-loaded PRV uses gas pressure applied to a dome to control downstream pressure. It offers exceptional stability and repeatability.

Key Engineering Characteristics

-

Exceptional accuracy and fine control

-

Fast response to pressure fluctuations

-

Suitable for high purity and high pressure systems

-

Compatible with automation and remote control

Typical Industry Use

These valves are commonly installed in:

-

Pharmaceutical processing

-

Biotechnology and bioreactors

-

Clean steam systems

-

High-purity gas distribution

-

Corrosive chemical service

Dome-loaded PRVs are often selected for processes where even small pressure variations can affect product safety or quality.

Comparison of PRV Types

| PRV Type | Accuracy | Flow Capacity | Best Used In |

|---|---|---|---|

| Direct-acting | Medium | Low–Medium | Air, water, inert gases |

| Pilot-operated | High | High | Steam, reactors, refineries |

| Dome-loaded | Very High | Medium | Pharma, biotech, high-purity gas |

Industries That Rely on Pressure Reducing Valves

Oil & Gas

Used for natural gas distribution, steam regulation, flare systems and pressure balancing in refinery units.

Pharmaceutical Manufacturing

Essential for purified water loops, clean steam systems, nitrogen supply and sterile utility lines.

Water Treatment & Desalination

Used for RO system protection, filtration units, pump discharge stabilization and distribution pipelines.

Chemical Processing

Protects reactors, heat exchangers, process vessels and hazardous fluid lines from overpressure.

Food & Beverage Industry

Ensures stable pressure for CIP units, heating systems, packaging lines and sanitary utilities.

Frequently Asked Questions

1. What is the purpose of a pressure reducing valve?

It maintains a fixed downstream pressure despite fluctuations in inlet pressure.

2. Which PRV type is most accurate?

The dome-loaded PRV provides the highest precision and repeatability.

3. Where are pressure reducing valves used?

They are used in pharmaceuticals, oil & gas, chemical plants, water treatment systems and power generation.

4. What affects PRV performance?

Flow demand, media type, pressure range, temperature and valve design influence PRV performance.

Why Pressure Reducing Valves Matter

Pressure reducing valves remain essential for ensuring safe and stable operation across all process industries. By understanding the differences among Direct-acting, Pilot-operated and Dome-loaded PRVs, engineers can select the correct valve type for each application. Proper PRV selection leads to improved efficiency, reduced downtime and enhanced equipment protection.