In pressurized fluid systems, higher pressure does not always translate into better performance. In fact, excessive pressure often leads to energy waste, mechanical damage, vibration, and unstable flow conditions. This is why Pressure Reducing Valves (PRVs) and Pressure Reducing Stations (PRS) are widely used across modern industrial plants. From steam networks to pharmaceutical water systems, these devices play a critical role in maintaining safe, stable, and efficient operation.

What Does a Pressure Reducing Valve Do?

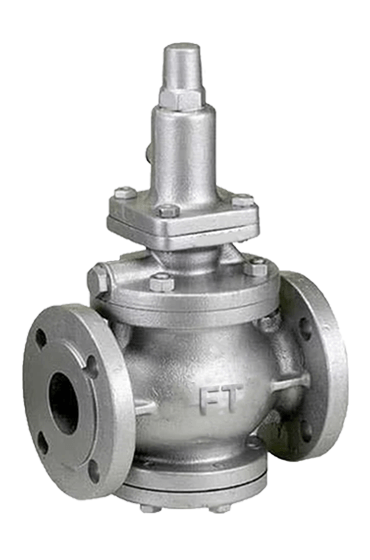

A Pressure Reducing Valve is an automatic control valve designed to reduce a higher inlet pressure to a stable and pre-set downstream pressure. It continuously senses the downstream pressure and adjusts the valve opening accordingly. When downstream pressure rises above the set value, the valve partially closes. When pressure drops, it opens to allow more flow.

This self-regulating function ensures that downstream equipment receives fluid at a safe and consistent pressure regardless of fluctuations in upstream pressure or system demand. As a result, sensitive components such as heat exchangers, filters, control valves, and pipelines are protected from pressure overload.

What Is a Pressure Reducing Station?

A Pressure Reducing Station is a complete engineered assembly that supports the safe and reliable operation of a PRV. Instead of installing individual components separately, the PRS integrates all essential accessories into one functional system.

A typical pressure reducing station includes:

-

Inlet and outlet isolation valves

-

Strainer or filter

-

Pressure reducing valve

-

Upstream and downstream pressure gauges

-

Safety relief valve

-

Bypass line

This configuration ensures clean fluid entry, accurate pressure monitoring, emergency over-pressure protection, and uninterrupted operation during maintenance.

Efficiency Benefits of Pressure Reduction

Operating a system at unnecessarily high pressure results in significant energy loss. Higher pressure increases frictional resistance in pipelines, which leads to higher pumping or compression power requirements. By reducing pressure to the actual level required by the process, PRVs minimize turbulence, reduce friction losses, and lower energy consumption.

Pumps, compressors, and boilers also operate more efficiently when they are not forced to maintain excess pressure. This directly reduces electricity usage and fuel consumption, making PRVs an important tool for energy-efficient plant operation.

Protection of Equipment

All mechanical components are designed to operate within defined pressure limits. When these limits are exceeded, the risk of seal failure, pipe deformation, valve leakage, and gasket blowouts increases dramatically.

Pressure reducing valves protect equipment by ensuring that downstream pressure never exceeds safe operating limits. This leads to:

-

Fewer unplanned shutdowns

-

Longer equipment life

-

Reduced maintenance cost

-

Improved plant reliability

In high-value systems such as pharmaceutical utilities or high-pressure steam networks, this protection is especially critical.

Types of Pressure Reducing Valves

Different industrial applications require different types of PRVs. The most commonly used include:

-

Direct-acting PRVs – Compact and simple, suitable for small flow rates

-

Pilot-operated PRVs – Used for high-flow and high-pressure systems requiring precise control

-

Steam pressure reducing valves – Designed to handle high temperature and condensate

-

Water pressure reducing valves – Used in potable and process water systems

-

Gas regulating valves – Designed for compressed air, nitrogen, and industrial gases

Each type is engineered to match specific operating conditions, ensuring reliable and stable pressure control.

Typical Industrial Applications

Pressure reducing valves and stations are widely used in:

-

Boiler and steam distribution systems

-

Cooling and chilled water networks

-

Pharmaceutical purified water and WFI systems

-

Compressed air supply lines

-

Chemical dosing and processing systems

Any industry that uses pressurized fluid relies on PRVs to maintain safety and process stability.

System Reliability and Safety

A well-designed pressure reducing station ensures continuous and safe operation. The bypass line allows maintenance of the PRV without shutting down the process. The safety relief valve protects the system in case of valve failure or sudden pressure spikes. Pressure gauges provide real-time performance monitoring, enabling operators to detect abnormalities early.

Pressure Reducing Valves and Pressure Reducing Stations are not just pressure control devices—they are powerful tools for energy efficiency, safety, and equipment protection. By stabilizing pressure, they reduce operating costs, extend equipment life, and improve overall system reliability. In any modern industrial plant, a properly designed pressure reducing system is an essential element of high-performance engineering.