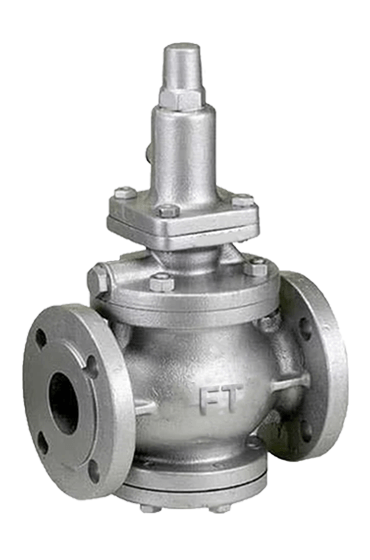

A Pressure Reducing Valve (PRV) is a critical component in fluid control systems, designed to regulate downstream pressure regardless of fluctuations in the upstream supply. From water treatment systems and industrial processing plants to HVAC and gas pipelines, pressure reducing valves ensure optimal system performance, safety, and energy efficiency.

In industries where consistent pressure is vital, the role of a pressure reducing valve cannot be overstated. Without proper pressure regulation, components can wear out prematurely, pipes may rupture, and overall system efficiency drops significantly.

What Is a Pressure Reducing Valve and How Does It Work?

A pressure reducing valve works by throttling the flow of fluid through an adjustable internal mechanism, often a spring-loaded diaphragm or piston. As the pressure increases upstream, the valve automatically reduces the pressure downstream to a set, safe level.

Unlike relief valves, which open only when pressure exceeds a certain limit, PRVs maintain a constant outlet pressure. This makes them ideal for systems requiring steady downstream pressure over long durations.

Applications of Pressure Reducing Valves

Pressure reducing valves are commonly used in the following sectors:

-

Water Supply Systems – To reduce pressure from municipal water mains to levels suitable for residential or commercial buildings.

-

Boiler and Steam Systems – To maintain pressure in steam pipelines, ensuring safety and energy efficiency.

-

Compressed Air Systems – To protect tools and downstream equipment from damage caused by excessive air pressure.

-

Chemical and Pharmaceutical Plants – To control pressure in sensitive systems where process stability is critical.

-

Oil and Gas Industries – To manage pressure in refining, distribution, and production lines.

Whether for water, gas, steam, or air, selecting the right pressure reducing valve manufacturer is vital to system integrity.

Key Benefits of Using Pressure Reducing Valves

-

Enhanced Safety: Overpressure can lead to burst pipes, leaks, and equipment failure. PRVs mitigate these risks by maintaining safe pressure levels.

-

Improved Energy Efficiency: Reducing unnecessary pressure helps decrease energy usage in pumping and heating systems.

-

Extended Equipment Life: Valves, pumps, and pipelines last longer under regulated pressure conditions.

-

Stable System Performance: Fluctuating pressure can affect product quality or cause system instability. PRVs deliver consistent output.

-

Cost Savings: Preventing damage and optimizing efficiency ultimately leads to lower maintenance and operational costs.

Types of Pressure Reducing Valves

At Freture Techno Pvt. Ltd., we manufacture a wide range of pressure reducing valves to suit different industrial applications:

-

Direct-Acting PRVs: Simple in design, ideal for low-flow systems where fine control is not required.

-

Pilot-Operated PRVs: Used for high-flow systems, these valves provide precise pressure regulation and respond quickly to load changes.

-

Spring-Loaded Diaphragm Valves: Common in water and air systems, these valves are reliable and low-maintenance.

-

Balanced Piston Valves: Suitable for high-pressure steam or gas systems where stable performance is essential.

Each valve is engineered to ensure maximum reliability and performance under demanding conditions.

Choosing the Right Pressure Reducing Valve

When selecting a pressure reducing valve, consider the following parameters:

-

Fluid Type: Different materials are required for water, steam, air, or corrosive fluids.

-

Flow Rate and Pressure Range: The valve must match the system’s pressure and flow demands.

-

Valve Material: Stainless steel, brass, and bronze are common, chosen based on media compatibility.

-

Installation Orientation: Horizontal and vertical mounting may affect valve performance and design selection.

-

Maintenance Requirements: Look for valves that are easy to access and service, minimizing downtime.

Freture Techno Pvt. Ltd. offers customized pressure reducing valve solutions tailored to meet specific industrial requirements.

Why Choose Freture Techno Pvt. Ltd. for Pressure Reducing Valves?

As a leading pressure reducing valve manufacturer in India, Freture Techno Pvt. Ltd. provides high-quality valves backed by precision engineering, durability, and compliance with global standards. Our valves are manufactured to deliver superior performance, even in the most demanding environments.

With a focus on innovation, we offer cutting-edge pressure control solutions to clients across industries including pharmaceuticals, oil and gas, water treatment, and more. Each valve is rigorously tested for performance, leak integrity, and longevity.

Conclusion

A Pressure Reducing Valve is essential to maintaining system safety, efficiency, and performance in fluid control applications. From steam systems to water pipelines, choosing the right PRV ensures smoother operations and long-term savings.

If you're seeking high-performance pressure reducing valves, trust Freture Techno Pvt. Ltd. – your reliable partner for industrial valve solutions in Mumbai, India and beyond.